Comprehensive Insights into Edge Breakage

What Constitutes Edge Breakage?

Protecting Edges from Breakage: Edge breakage is the failure of edges in various materials or structures, commonly caused by stress concentration and material fatigue. Gaining a thorough understanding of this concept is essential, as edge vulnerability can dramatically affect the longevity and overall performance of a wide range of products across diverse sectors. Several typical scenarios that illustrate the risks linked to edge breakage include:

- Impact from regular handling or movement of items.

- Exposure to extreme temperatures that compromise material integrity.

- Corrosive environments that lead to weakened edges over time.

- Fatigue resulting from repetitive use of machinery or tools.

- Manufacturing inconsistencies that result in inherently weaker edges.

- Improper storage methods may lead to accidental chipping.

- Unbalanced loads that generate stress concentrations.

- Environmental factors such as humidity and UV exposure exacerbate vulnerabilities.

The consequences of edge breakage can vary significantly—from merely cosmetic damage to potentially catastrophic failure—depending on the specific application and material involved. Identifying the underlying causes of edge breakage is vital for implementing effective preventative strategies that enhance durability and performance.

Critical Elements Influencing Edge Wear

Numerous factors contribute to the gradual degradation of edges, which can jeopardise the integrity and usability of various materials. Factors such as environmental conditions, mechanical stress, and material composition play pivotal roles in edge wear. Common everyday influences that significantly impact the longevity of edges include:

- Frequent contact with other surfaces during normal operations.

- Fluctuations in temperature and humidity can weaken structures.

- Physical stress resulting from handling or application in various contexts.

- Chemical exposure due to cleaning substances or environmental pollutants.

- Improper maintenance practices that fail to address wear factors.

A comprehensive understanding of these contributing factors enables the implementation of proactive measures that ensure edge durability, ultimately enhancing the lifespan of both products and structures. By effectively addressing these challenges, organisations can improve their operational efficiency and reduce the risk of unexpected failures.

How to Identify Early Signs of Damage

Recognising early indicators of potential edge damage is imperative for timely intervention and mitigation. Subtle changes, such as visible chipping, fraying, or discolouration, often signal underlying weaknesses that could escalate into serious issues. Monitoring these signs is crucial for preserving structural integrity and preventing severe damage. Effective strategies for monitoring edge conditions include:

- Conducting regular visual inspections to identify any surface irregularities or signs of wear.

- Utilising stress testing methods to evaluate material performance thoroughly.

- Implementing routine maintenance checks to ensure compliance with safety protocols.

- Maintaining detailed logs of wear and tear over time to anticipate future failures.

By remaining vigilant and proactive in monitoring edge conditions, both individuals and organisations can take the necessary steps to rectify minor issues before they escalate into major failures, thereby ensuring ongoing safety and reliability.

Effective Strategies for Preventing Edge Breakage

To effectively prevent edge breakage, it is essential to select robust materials, optimise designs for effective stress distribution, and implement regular maintenance routines. These proactive steps not only enhance the longevity of materials but also significantly reduce the risk of failure. Educating users on safe handling practices can considerably improve performance across diverse applications. Effective strategies to consider include:

- Selecting materials known for their resilience and durability under various conditions.

- Designing components to minimise stress concentration at critical edges.

- Scheduling regular maintenance to inspect and reinforce edges systematically.

- Training personnel on proper handling techniques to avoid accidental damage during operations.

Implementing these comprehensive strategies ensures that products remain functional, safe, and effective, significantly extending their useful life and reducing maintenance costs.

Repair Techniques for Addressing Damaged Edges

Effectively repairing damaged edges requires precise tools and methods to restore structural integrity. Techniques such as grinding, welding, or patching can effectively address edge fractures or chips. Timely interventions are critical in preventing the escalation of issues that could lead to complete failure. It is equally essential to emphasise safety protocols and material compatibility during repairs. Techniques worth considering include:

- Grinding down damaged areas to create a smooth surface for subsequent repairs.

- Welding to fuse broken edges back together, ensuring strength and security.

- Utilising epoxy or adhesive compounds for addressing minor cracks and chips.

- Applying protective coatings post-repair to prevent future damage and enhance durability.

Properly executed repairs can significantly extend the lifespan of components while minimising replacement costs, thereby contributing to overall operational efficiency.

Identifying Common Causes of Edge Breakage

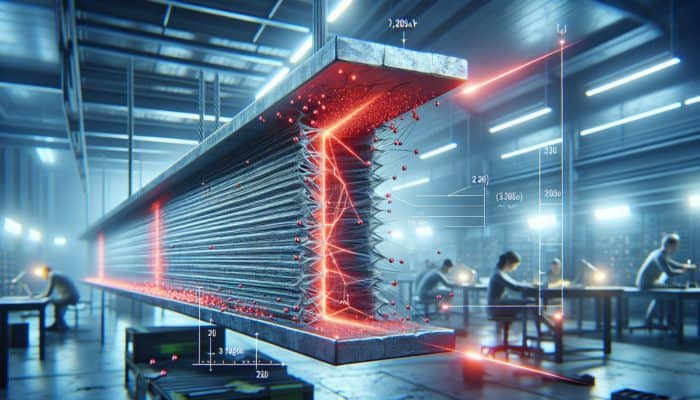

Understanding Material Stress Points

Material stress points are specific areas where forces converge, often leading to edge failure. These stress points can arise from various sources, such as uneven loading or abrupt impacts during use. Understanding how forces affect structures universally is key to devising effective prevention strategies. To mitigate these stress-related issues, organisations should consider the following:

- Reinforcing edges with additional material or innovative design features.

- Implementing load distribution techniques to minimise stress concentrations at critical points.

- Conducting simulations to identify potential stress points during the design phase, enabling preemptive action.

- Utilising shock-absorbent materials in high-impact applications to safeguard edges.

By proactively addressing stress points, organisations can significantly reduce the likelihood of edge breakage, enhancing overall product reliability.

Wear and Tear from Daily Use

Routine activities can inadvertently accelerate edge damage, leading to premature material failure. Everyday exposure effects, such as friction and abrasion, can gradually wear down edges, necessitating protective measures. Simple strategies to minimise wear include:

- Use protective coverings or edge guards during regular handling to shield vulnerable areas.

- Implementing gentle handling protocols to reduce abrasive contact with edges during use.

- Regular cleaning of edges to remove debris that may cause abrasion and wear.

- Educating users on the importance of careful handling techniques to extend the life of edges.

These preventive measures can significantly extend the lifespan of edges across various applications, ensuring continued performance and user safety.

How Do External Forces Contribute to Edge Breakage?

External forces significantly influence edge breakage, affecting materials and structures across numerous environments. Factors such as environmental conditions, impact forces, and unexpected loads can exacerbate edge vulnerabilities. To mitigate these risks effectively, it is essential to implement actionable strategies, including:

- Utilising weather-resistant materials for applications exposed to outdoor conditions.

- Securing items properly during transport to prevent movement that could lead to impact damage.

- Conducting regular assessments of external influences on material integrity to maintain optimal performance.

- Adopting flexible designs that can accommodate movement and pressure changes without compromising edges.

By understanding and addressing the impact of external forces, organisations can significantly reduce the risk of edge breakage, enhancing overall material durability and safety.

Manufacturing Defects and Their Impact

Inconsistencies in production processes often create vulnerable edges that are particularly prone to breakage. Typical fabrication errors, such as poor material selection or flawed design, can undermine a product's overall strength and integrity. Analysing these manufacturing defects is vital for enhancing quality assurance protocols. To prevent issues stemming from defects, organisations should consider:

- Implementing stringent quality control measures throughout the production process to ensure compliance with standards.

- Conducting thorough testing of materials before fabrication to identify potential weaknesses.

- Utilising advanced manufacturing techniques designed to eliminate inconsistencies and enhance quality.

- Providing comprehensive training for personnel on recognised best practices in manufacturing to reduce errors.

By adopting these measures, manufacturers can significantly bolster the structural integrity of their products, thereby mitigating the risk of edge breakage and ensuring reliability.

What Practical Steps Can Prevent Edge Breakage?

Basic Protective Techniques to Safeguard Edges

Simple yet effective methods exist to safeguard edges against potential harm. Implementing straightforward approaches in everyday applications can significantly reduce the likelihood of breakage. Techniques that are easy to incorporate include:

- Applying edge guards or bumpers to sensitive surfaces that are prone to damage.

- Utilising storage solutions designed to minimise impact on edges during storage and transport.

- Establishing specific handling protocols to reduce accidental contact during operations.

- Regularly inspecting and maintaining edges to catch wear or damage early.

These basic protective techniques create a safer environment for materials and structures, promoting their durability, functionality, and overall longevity.

Innovative Solutions for Enhancing Edge Strength

Advanced ideas and technologies can enhance edge resilience, providing innovative tools and methods for protection. Employing these strategies can significantly improve durability and performance over time. Effective options to boost edge strength include:

- Utilising composite materials that offer added toughness and impact resistance for improved protection.

- Applying impact-resistant coatings that enhance the durability of edges against various forms of damage.

- Incorporating design features that redirect force away from edges to reduce stress concentration.

- Employing 3D printing techniques to create custom protective solutions tailored to specific applications.

These innovative solutions not only enhance edge resilience but also challenge traditional manufacturing and design practices, thereby improving material performance.

Monitoring for Long-Term Longevity

Regular checks are essential for ensuring that edges remain intact and functional over time. Consistent monitoring practices can help identify signs of wear before they lead to significant failure. The benefits of vigilance in this context are substantial, including:

- Early detection of potential issues that could escalate into serious damage.

- Improved planning for maintenance and replacement schedules based on observed conditions.

- Enhanced safety through proactive measures that mitigate risk.

- Extended lifespan for materials and structures through timely interventions and repairs.

By fostering a culture of thorough monitoring, individuals and organisations can significantly bolster the durability of their products and ensure continued reliability and safety.

Expert Insights into Effective Edge Protection Strategies

What Insights Do Experts Provide on Edge Protection?

In-depth reviews and analyses by experts uncover key protection strategies vital to maintaining edge integrity. These expert evaluations often include real-world examples of successful applications that highlight effective measures. Actionable steps based on studies in this area include:

- Utilising data-driven approaches to assess edge vulnerabilities and identify areas for improvement.

- Conducting case studies on failed edges to inform better practices and design improvements.

- Engaging in collaborative efforts to share findings and strategies among professionals.

- Implementing pilot programmes before the widespread adoption of new techniques to assess their effectiveness.

Expert analysis provides invaluable insights that can elevate protective strategies for edges, ensuring that best practices are widely adopted and continuously refined for enhanced effectiveness.

Exploring Advanced Reinforcement Methods

Specialised techniques can significantly enhance edge strength by drawing on a wealth of expertise across various fields. Expert analysis of material enhancements can provide clarity on how to improve edge durability. Recommended methods include:

- Incorporating fibre-reinforced composites for added strength and resilience in critical applications.

- Utilising advanced bonding techniques to improve adherence and structural integrity.

- Implementing thermal treatments to enhance the properties of materials, ensuring better performance.

- Exploring non-destructive testing methods to assess edge integrity without compromising the material.

These advanced reinforcement methods represent a forward-thinking approach to edge protection that can be tailored to meet the specific needs of various applications and environments, ultimately improving outcomes and safety.

Evaluating the Effectiveness of Protection Measures

Assessing the effectiveness of protection measures is critical for optimisation and continuous improvement. Trusted strategies can help in evaluating the overall effectiveness of edge protection initiatives. Recommendations for this assessment process include:

- Establishing clear metrics for measuring protective outcomes and success rates.

- Conducting periodic reviews of protective measures and their performance against established benchmarks.

- Utilising feedback loops to gather insights from users and stakeholders regarding their experiences.

- Implementing iterative improvements based on evaluation findings to refine strategies continuously.

A structured approach to evaluating effectiveness ensures that organisations can continuously enhance their edge protection strategies, ultimately improving reliability and safety.

What Materials Are Most Effective in Edge Protection?

Identifying the Ideal Materials for Edge Protection

Selecting substances that resist breakage is critical for ensuring durability across various applications. Exploring the properties and strengths of materials can reveal their versatility in different contexts. Ideal choices for effective edge protection include:

- High-density polyethene (HDPE) is used for its superior impact resistance and durability.

- Aluminium alloys that offer lightweight yet sturdy solutions for a range of applications.

- Composite materials that combine the strengths of different substances for enhanced performance.

- Glass fibre-reinforced plastics are known for their high strength-to-weight ratios, making them suitable for critical applications.

By selecting the right materials, organisations can significantly enhance edge resilience, safeguarding them against potential breakage and ensuring long-term performance.

How to Effectively Apply Protective Coatings?

Applying protective coatings effectively can create a robust defence against edge damage, significantly enhancing durability. Understanding the application process and common errors is essential for achieving optimal results. Key tips for a successful application include:

- Ensuring thorough surface cleaning before application to promote better adhesion and effectiveness.

- Applying coatings in controlled environmental conditions to avoid issues such as bubbling or uneven application.

- Meticulously following manufacturer guidelines for application techniques to ensure proper coverage.

- Conducting regular inspections after application to monitor integrity and effectiveness over time.

When correctly applied, protective coatings can significantly improve edge durability, prolonging the lifespan of materials and structures while enhancing their overall integrity.

Combining Materials for Superior Edge Protection

Integrating various materials to enhance durability can yield synergistic effects that significantly improve edge protection. Discussing compatibility between different materials is essential to ensure effective combinations. Considerations for successful integration include:

- Testing various combinations under stress conditions to determine optimal pairings for edge protection.

- Utilising layers of different materials to exploit their unique strengths and enhance overall resilience.

- Investigating the benefits of coatings or treatments on base materials to improve performance.

- Exploring hybrid structures that incorporate both rigid and flexible components for adaptive protection.

Such integrative approaches can lead to remarkable improvements in edge durability, ensuring products remain reliable and safe throughout their lifecycle.

Time-Tested Strategies for Protecting Edges from Breakage

Core Principles of Effective Edge Defence

Reliable tactics play a crucial role in preventing edge damage. Incorporating expert phrasing into actionable steps can enhance the immediate effectiveness of these strategies. Core principles to consider include:

- Understanding the unique requirements and vulnerabilities of different materials to tailor protection.

- Implementing multi-layered protective strategies for comprehensive coverage against a range of threats.

- Educating personnel on the importance of adherence to protective protocols to enhance compliance.

- Regularly updating protection measures to align with evolving industry standards and best practices.

These principles serve as a foundation for robust edge protection measures that enhance safety and reliability across diverse applications.

Layered Protection Approaches for Enhanced Resilience

Building multiple layers of defence against edge damage provides heightened resilience and protection. Practical applications can illustrate the advantages of layered protection strategies. Examples of effective techniques include:

- Combining physical barriers with chemical treatments for enhanced defence against wear and tear.

- Utilising various coatings that offer distinct protective benefits tailored to specific vulnerabilities.

- Employing both mechanical and environmental protections concurrently for comprehensive coverage.

- Implementing feedback from previous failures to inform layered designs and improve overall effectiveness.

Layered protection strategies not only bolster edge resilience but also demonstrate a comprehensive understanding of the potential vulnerabilities that can be effectively addressed.

Why Is Routine Care Critical for Edge Protection?

Regular maintenance is vital for preventing breaks, as neglect can lead to significant damage over time. Expert analysis reveals the long-term benefits of consistent maintenance routines. Key benefits include:

- Improved performance longevity for materials and structures through timely interventions.

- Reduced costs associated with repairs and replacements by addressing issues before they escalate.

- Enhanced safety through the prevention of catastrophic failures that could endanger users.

- Greater reliability of products under varying conditions, ensuring consistent performance.

Focusing on routine care ensures that edges remain protected and functional throughout their lifespan, ultimately contributing to overall efficiency and safety.

Why Is Edge Protection Essential for Safety and Performance?

Benefits of Preventing Edge Breakage

Preventing edge breakage offers several key advantages, including enhanced safety and improved operational efficiency. Understanding how these benefits impact overall performance is crucial for stakeholders. The widespread implications include:

- Reduction of injury risks associated with sharp or damaged edges that could cause accidents.

- Increased operational efficiency through reduced downtime for repairs and maintenance.

- Improved aesthetic value of products through maintained integrity and appearance.

- Enhanced customer satisfaction as a result of reliable products that perform consistently.

The benefits of preventing breakage extend beyond immediate safety concerns, contributing to overall operational efficiency and long-term success across industries.

Long-Term Value of Strategic Safeguards

Investing in protective measures yields enduring rewards, particularly in terms of cost savings and reliability over time. Considerations should include comparisons of outcomes associated with protective investments and their long-term impacts. Long-term values encompass:

- Lower total cost of ownership through reduced maintenance needs and fewer replacements.

- Extended product life cycles lead to better investment returns and greater sustainability.

- Increased trust and loyalty from customers who value durability and performance consistency.

- Minimised environmental impact through reduced waste from discarded or damaged products.

The long-term value of safeguards justifies the initial investment, reinforcing the importance of implementing robust edge protection strategies in all relevant applications.

Identifying Common Oversights in Edge Protection

Frequent errors can undermine efforts to protect edges, leading to significant consequences that compromise safety and performance. Identifying these oversights is essential for continuous improvement and effectiveness. Questions surrounding their effects include:

- Are protective measures regularly updated to reflect new findings and industry standards?

- Is there sufficient training provided for personnel on protective protocols and procedures?

- Are maintenance schedules adhered to consistently to ensure ongoing protection?

- Is there a feedback mechanism in place to capture user experiences and insights for improvement?

By addressing these common oversights, organisations can significantly enhance their protective strategies, ultimately improving safety and performance across the board.

Long-Term Strategies for Sustained Durability

Planning for Ongoing Edge Health

Developing ongoing plans to maintain edge integrity is vital for ensuring long-term durability and performance. Focusing on adaptive measures allows for effective management of edge conditions as they evolve. Progressive steps to consider include:

- Establishing regular assessment schedules to monitor edge conditions and identify wear.

- Implementing contingency plans for unexpected environmental changes that may affect materials.

- Allocating resources for proactive maintenance and upgrades to enhance durability.

- Engaging in continuous education on emerging protective technologies and practices.

Long-term strategies for edge health contribute significantly to the overall performance, safety, and reliability of materials across various applications.

Adapting to Changing Conditions for Effective Protection

Adjusting strategies as operational needs evolve is crucial in maintaining edge protection. Discussing flexible responses allows for better management of unforeseen circumstances and challenges. Emphasising proactive adjustments can include:

- Regularly reviewing and updating protective measures based on new insights and industry advancements.

- Implementing adaptive designs that can accommodate operational changes without compromising effectiveness.

- Establishing partnerships with experts for ongoing guidance and support in edge protection.

- Utilising data analytics to predict potential vulnerabilities and proactively address them.

By remaining adaptable and responsive to changing conditions, organisations can ensure that edge protection measures continue to meet their evolving needs and challenges effectively.

Measuring Success Over Time for Continuous Improvement

Tracking improvements in edge resilience requires evaluating metrics for effectiveness and performance. Guidelines for assessment should focus on measurable outcomes that inform future strategies. Effective strategies include:

- Establishing baseline metrics for edge durability to track improvements over time.

- Conducting regular evaluations to quantify enhancements and identify areas for further improvement.

- Gathering user feedback on protective effectiveness and suggestions for refinement.

- Using statistical analysis to identify trends and areas for enhancement in edge protection strategies.

A structured approach to measuring success enables organisations to make informed decisions about their edge protection strategies, thereby enhancing reliability, safety, and operational efficiency.

Frequently Asked Questions

What Are the Common Causes of Edge Breakage?

Common causes of edge breakage include material stress points, wear from daily use, external forces, and manufacturing defects that compromise edge integrity over time, leading to potential failures.

How Can I Prevent Edge Breakage in Tools?

Preventive measures to avert edge breakage in tools include using protective covers, implementing careful handling protocols, and conducting regular inspections to identify wear early and address it promptly.

What Materials Are Best for Edge Protection?

Ideal edge protection materials include high-density polyethene, aluminium alloys, and composite materials that offer excellent impact resistance and durability across various applications.

How Often Should I Check for Signs of Edge Damage?

Regular inspections should be conducted at least once a month or after any significant use or environmental exposure to ensure early detection and mitigation of potential issues.

Are There Specific Coatings for Edge Protection?

Yes, a variety of coatings are specifically designed for edge protection, including epoxy, polyurethane, and weather-resistant paints that enhance durability and resistance to wear and tear.

What Role Does Routine Maintenance Play in Edge Protection?

Routine maintenance is essential for preventing edge breakage, as it enables timely interventions, extends the lifespan of materials, and enhances overall safety through consistent care.

Can I Repair Damaged Edges Myself?

Minor repairs can often be performed independently using appropriate tools and techniques, but complex repairs may require professional assistance to ensure optimal results and safety.

What Are the Benefits of Using Layered Protection Strategies?

Layered protection strategies enhance durability by combining multiple defence mechanisms that address various forms of edge damage, resulting in improved overall safety and performance.

How Do I Know If My Edge Protection Measures Are Effective?

Effectiveness can be measured through regular inspections, user feedback, and tracking the incidence of edge damage over time to evaluate improvements and refine strategies.

Is It Worth Investing in Advanced Edge Protection Technologies?

Yes, investing in advanced edge protection technologies often results in long-term cost savings and improved safety, making it a worthwhile consideration for many applications and industries.

Katalina Dean

January 26, 2026This post brings to light an often-overlooked aspect of material durability that has significant implications across various industries. I’ve come across edge breakage not only in machinery but also in everyday items, like kitchen knives or electronic devices. It’s fascinating how something as subtle as a poorly designed edge can lead to major failures, both in terms of safety and functionality.